-

Training

- Flow Cytometry Basic Training

-

Product-Based Training

- BD Accuri™ C6 Plus Cell Analyzer

- BD FACSAria™ Cell Sorter Cell Sorter

- BD FACSCanto™ Cell Analyzer

- BD FACSDiscover™ A8 Cell Analyzer

- BD FACSDiscover™ S8 Cell Sorter

- BD FACSDuet™ Sample Preparation System

- BD FACSLyric™ Cell Analyzer

- BD FACSMelody™ Cell Sorter

- BD FACSymphony™ Cell Analyzer

- BD LSRFortessa™ Cell Analyzer

- Advanced Training

Old Browser

This page has been recently translated and is available in French now.

Looks like you're visiting us from {countryName}.

Would you like to stay on the current location site or be switched to your location?

GMP Manufacturing and Quality Control

Cell therapy manufacturing and quality control (QC) in GMP environments has a number of challenges related to ensuring proper documentation, accurate and reproducible results, and scaling up for global manufacturing. To address these challenges, teams are investing in automated and easy-to-use flow cytometers, reagents manufactured according to GMP standards, software with features such as password protection, electronic signatures, automatic record keeping and audit trails that support 21 CFR Part 11 compliance, and lab information systems.

Optimizing manufacturing processes to reduce complexity and improve scalability requires the use of automated technologies. Flow cytometry solutions that are standardized across instruments allow data comparison and consistency of results across manufacturing sites and allow seamless tech transfers from research and development through to manufacturing.

Explore how BD flow cytometry solutions can support key requirements for cell therapy manufacturing QC:

The manufacturing of cell therapy products requires testing at multiple stages and thus requires a significant amount of time and effort to ensure that the instrumentation and assays deliver accurate results. This drives interest in methods to improve efficiency of these workflows.

The BD FACSLyric™ Flow Cytometer enables efficiency and productivity with:

- Distinctive assay portability feature that allows easy and efficient transfer of assays across sites

- Automated analysis using the BD ElastiGate™ Autogating Algorithm in the BD FACSuite™ Application v1.6, which enables 1.8X faster analysis

- Fluorescence compensation required only every 60 days

- Flexibility for acquisition using a universal loader with 21 different loading options including multiwell plates

- Automated laser alignment

In addition, flow cytometry sample preparation can be automated using the BD FACSLyric™ Flow Cytometer integrated with the BD FACSDuet™ Sample Preparation System. Benefits of this solution include:

- Physical integration of the sample preparation system with the flow cytometer to provide a complete end-to-end walkaway solution

- On-board, automated antibody cocktail preparation, washing, centrifugation and sample transfer that eliminates risk of errors due to manual pipetting

- Support for different types of blood collection tubes and a wide variety of reagent vials

Download the BD FACSDuet™ Premium Sample Preparation System brochure.

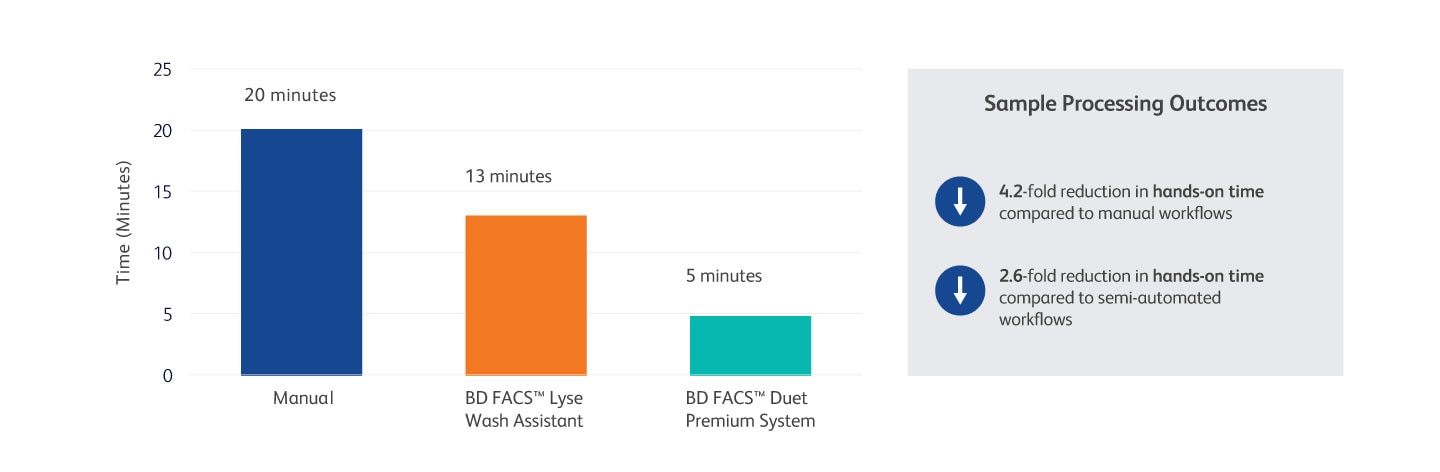

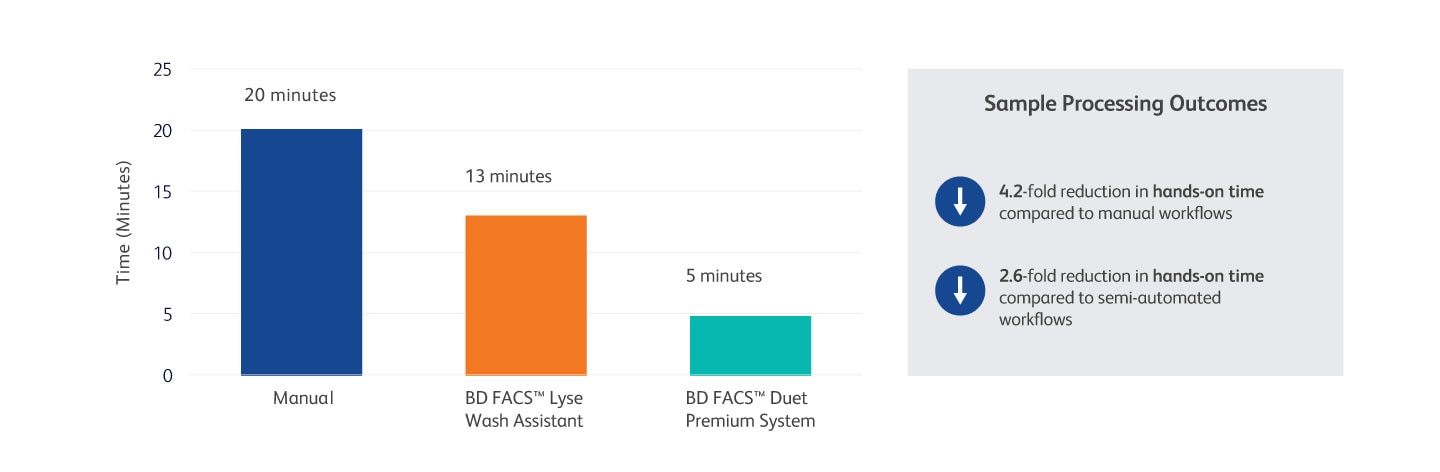

See below for data from a clinical lab demonstrating the reduction in hands-on time gained when using a BD FACSDuet™ System to automate a standard wash assay.

Reduce Operator Hands-on-time with the BD FACSDuet™ Premium System

Hands-on time for manual, BD FACS™ Lyse Wash Assistant and BD FACSDuet™ Premium System three samples, 15-tube workflows

Study conducted at a U.S. clinical lab. Three workflows were compared for total processing time and hands-on time for manual, BD FACS™ Lyse Wash Assistant and BD FACSDuet™ Premium Sample Preparation System workflows. This process uses pre-cocktailed reagents and begins with pulling reagents out of the fridge for manual/BD FACS™ Lyse Wash Assistant workflows or loading specimens onto the BD FACSDuet™ Premium System. Three specimens were run with an SLW assay with five tubes per specimen for a total of 15 tubes per workflow.

Consistent Reagent and Instrument Performance and Streamlined AssayTransfer Enables Global Standardization

Ensuring consistent performance across the globe is critical for the distributed manufacturing and testing commonly found in cell therapy manufacturing as well as producing quality clinical research data. BD Biosciences has developed robust methods to make this easier.

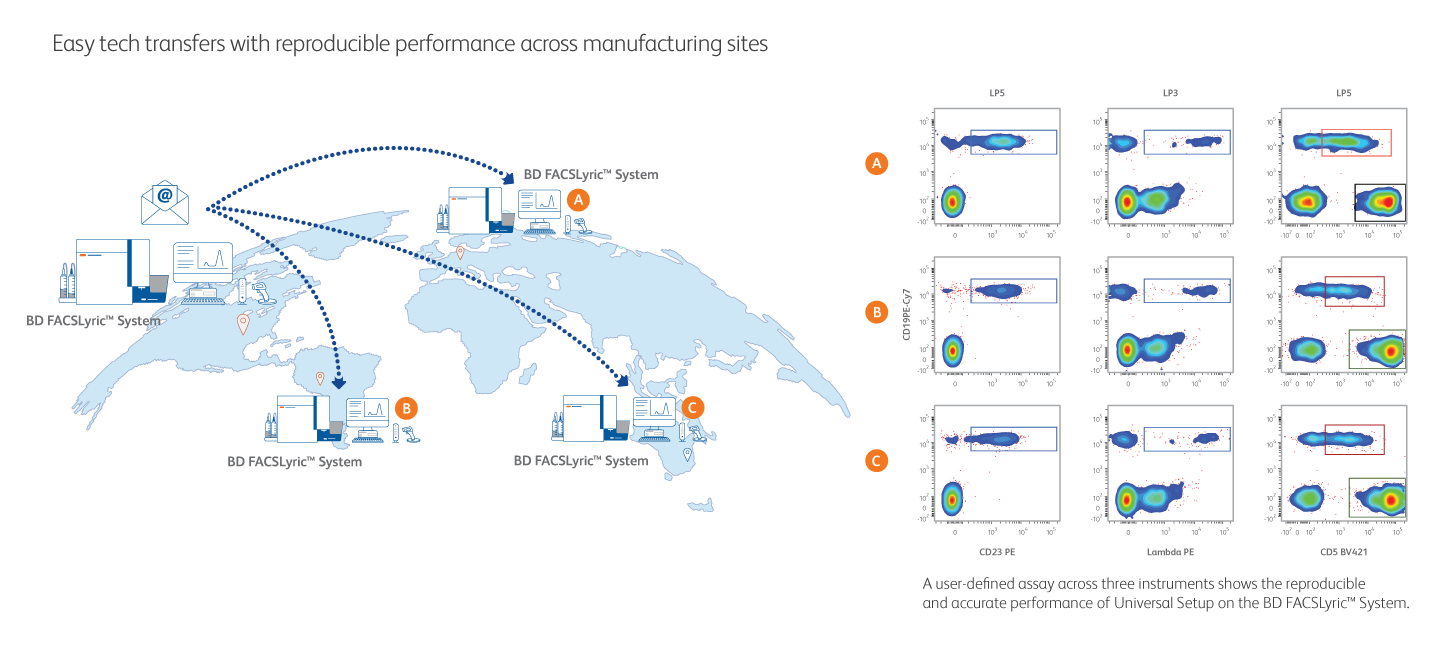

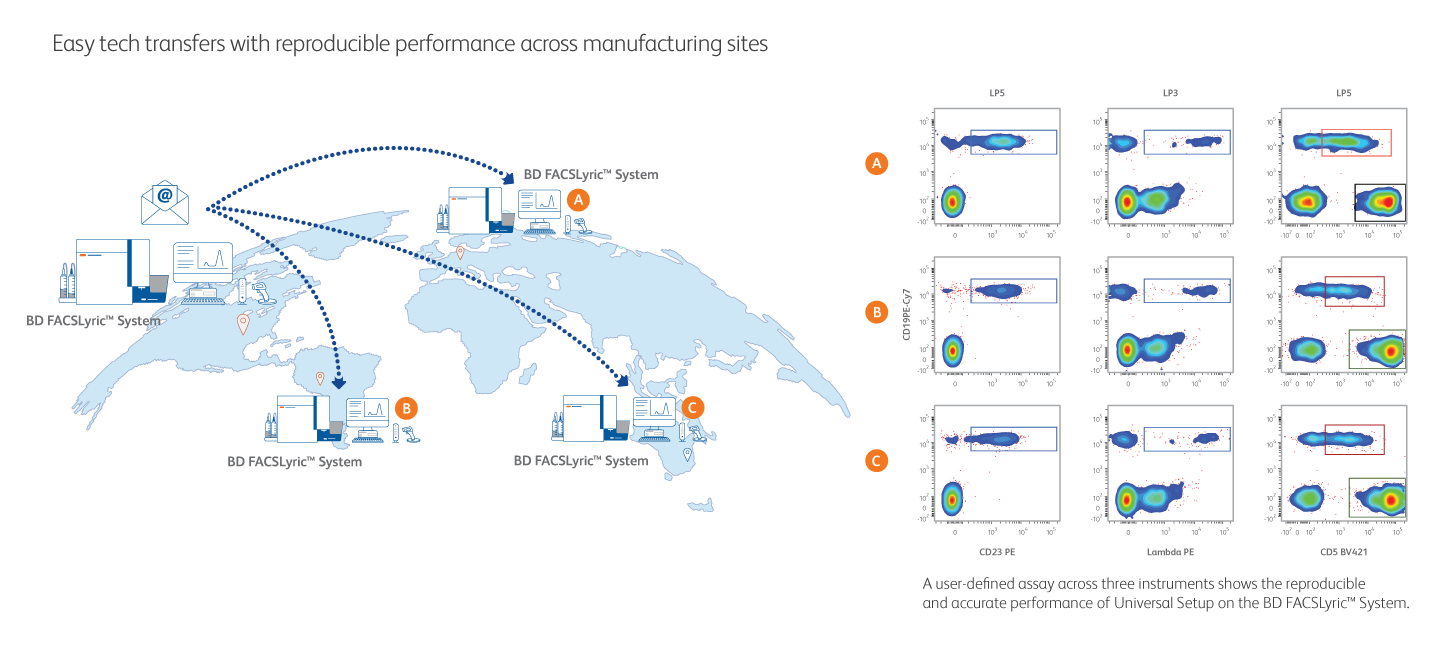

Streamlined Assay Transfer for Reproducible Performance Across Manufacturing Sites

Universal Setup on the BD FACSLyric™ Flow Cytometer allows transfer of user-defined assays from one instrument to another, supporting standardization of conditions for reproducibility across global manufacturing sites. This high-performance, highly sensitive flow cytometer demonstrates exceptional resolution and improved separation to make dim and rare populations easier to resolve.

The BD FACSDuet™ Sample Preparation System fully automates flow cytometry sample prep, including sample washing. The BD FACSDuet™ System adds traceability and automation to the preanalytical process.

BD Clinical Discovery Research Reagents are manufactured in a GMP environment to support your manufacturing QC assays. Using GMP reagents as part of your flow cytometry quality control helps to further standardize your manufacturing QC assay to give you confidence in the safety and integrity of your clinical research. Lot-to-lot consistency leads to results that increase confidence in the data and that it can be safe for translating into clinical use in the future.

BD RUO (GMP) Reagents are manufactured in accordance with Good Manufacturing Practices for devices under 21 CFR Part 820. Unit-sized preformulated and performance-optimized multicolor RUO/GMP panels are also available.

Custom multicolor panel solutions are also available to drive workflow efficiency and assay standardization. These reagents, defined by the customer, are manufactured using proprietary BD Horizon™ Chroma Dried Paneland are stable for 12–18 months at room temperature.

View Available RUO/GMP Reagents

A user-defined assay across three instruments shows the performance of Universal Setup on the BD FACSLyric™ System.

Functions in the BD FACSuite™ Application Assist in Supporting Your 21 CFR Part 11 Compliance and Electronic Record Integrity

Our flagship analyzer, BD FACSLyric™ Flow Cytometer, is upgradeable to a 12-color configuration. It is powered by the BD FACSuite™ Application used for acquisition and analysis that helps to support 21 CFR Part 11 compliance with password protection, electronic signatures, automatic record keeping and audit trails. We provide operational qualification (OQ) by a BD field service engineer for features related to 21 CFR Part 11 compliance for the BD FACSLyric™ Flow Cytometer and the BD FACSuite™ Application.

The BD FACSDuet™ Premium System allows traceability of samples and worklists through carrier barcoding and supports ISO 15189-accredited labs with compliance with complete workflow traceability.

Automated systems and software such as the BD FACSuite™ Application include built-in functional controls that helps to achieve compliance with the functional aspects of 21 CFR Part 11. However, there are limitations to what the tools can provide.

Learn how the BD FACSuite™Application functions and options support 21 CFR Part 11.

Webinar: 21 CFR Part 11 Compliance.

Learn about the:

- Background and overview of 21 CFR Part 11

- Importance of data security practices for open vs closed systems

- Crucial role software plays in enabling 21 CFR Part 11 compliance

- Guidelines for electronic signatures and records

Global Install Base with Guaranteed Technical Service Support

With BD as your single partner for flow cytometry reagents, instruments and services you will benefit from synergies in user workflows and support provided. BD Technical Services provide installation qualification (IQ), operational qualification (OQ) and technical service support to minimize instrument downtime. BD offers qualification assistance to help customers meet current Good Manufacturing Practice (cGMP) and Good Laboratory Practice (cGLP) standards. Explore our contract manufacturing offering of multicolor panels in liquid, dried or lyophilized formats to minimize errors and time associated with manual cocktailing of reagents.

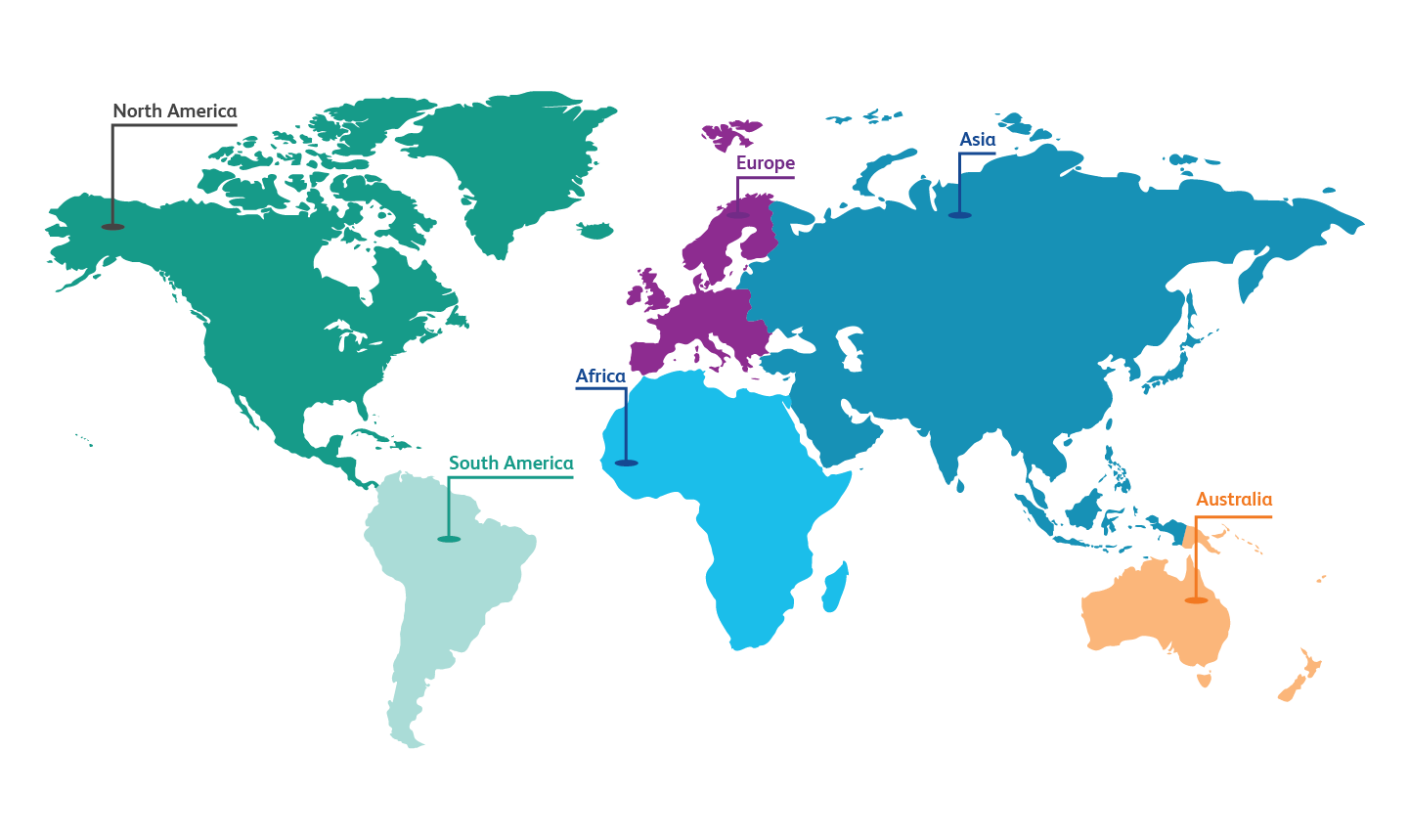

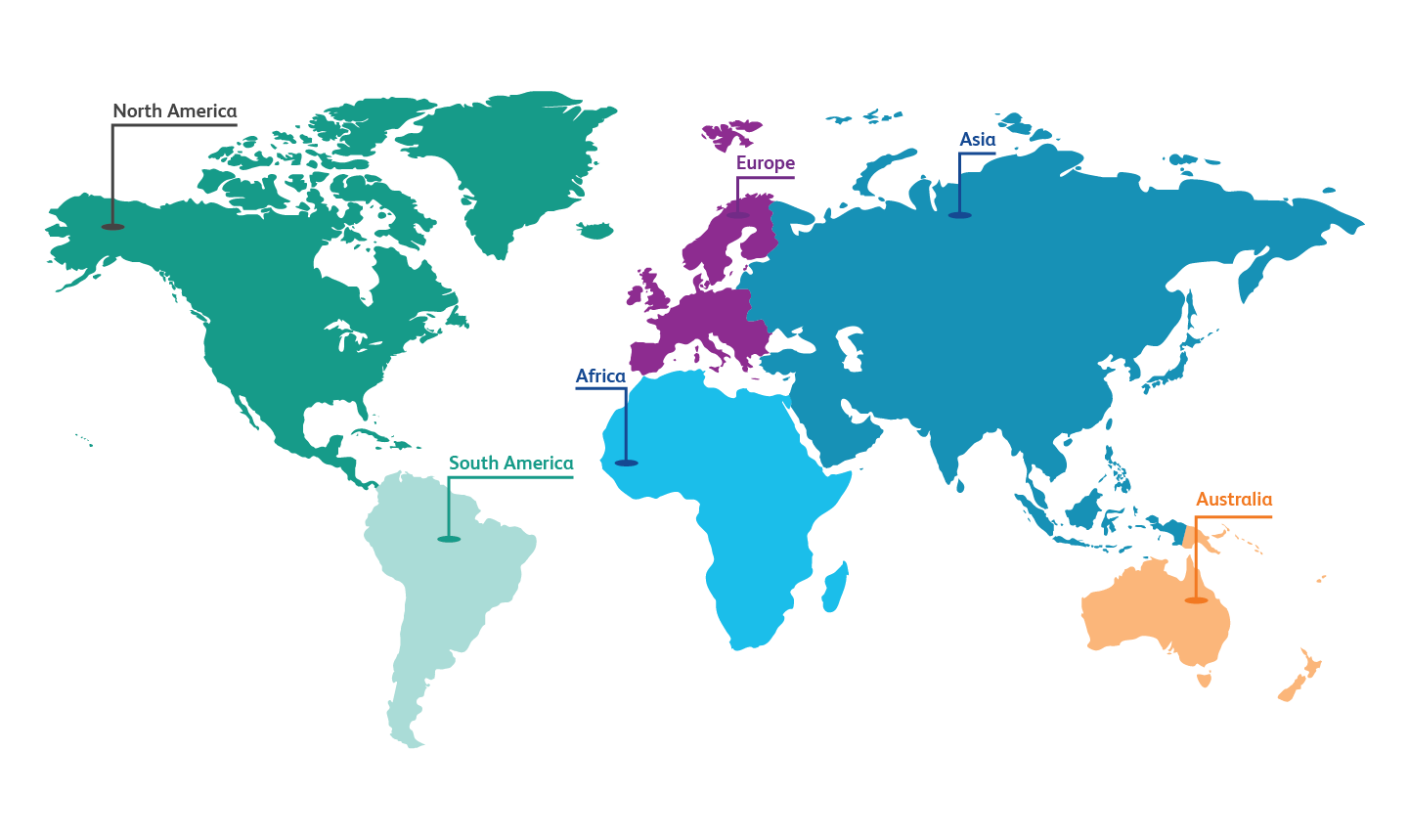

The BD FACSLyric™ Flow Cytometer has an install base of more than 3,000 units around the world. BD Biosciences has service engineers and application specialists available across North and South America, Africa, Europe and Asia to support your needs as you look to scale up operations.

All user-defined flow cytometry assays used for manufacturing and QC release of product must be validated and verified by the user. The user must comply with applicable local regulations and obtain appropriate health authority approval as necessary for their intended use.

The manufacturing of cell therapy products requires testing at multiple stages and thus requires a significant amount of time and effort to ensure that the instrumentation and assays deliver accurate results. This drives interest in methods to improve efficiency of these workflows.

The BD FACSLyric™ Flow Cytometer enables efficiency and productivity with:

- Distinctive assay portability feature that allows easy and efficient transfer of assays across sites

- Automated analysis using the BD ElastiGate™ Autogating Algorithm in the BD FACSuite™ Application v1.6, which enables 1.8X faster analysis

- Fluorescence compensation required only every 60 days

- Flexibility for acquisition using a universal loader with 21 different loading options including multiwell plates

- Automated laser alignment

In addition, flow cytometry sample preparation can be automated using the BD FACSLyric™ Flow Cytometer integrated with the BD FACSDuet™ Sample Preparation System. Benefits of this solution include:

- Physical integration of the sample preparation system with the flow cytometer to provide a complete end-to-end walkaway solution

- On-board, automated antibody cocktail preparation, washing, centrifugation and sample transfer that eliminates risk of errors due to manual pipetting

- Support for different types of blood collection tubes and a wide variety of reagent vials

Download the BD FACSDuet™ Premium Sample Preparation System brochure.

See below for data from a clinical lab demonstrating the reduction in hands-on time gained when using a BD FACSDuet™ System to automate a standard wash assay.

Reduce Operator Hands-on-time with the BD FACSDuet™ Premium System

Hands-on time for manual, BD FACS™ Lyse Wash Assistant and BD FACSDuet™ Premium System three samples, 15-tube workflows

Study conducted at a U.S. clinical lab. Three workflows were compared for total processing time and hands-on time for manual, BD FACS™ Lyse Wash Assistant and BD FACSDuet™ Premium Sample Preparation System workflows. This process uses pre-cocktailed reagents and begins with pulling reagents out of the fridge for manual/BD FACS™ Lyse Wash Assistant workflows or loading specimens onto the BD FACSDuet™ Premium System. Three specimens were run with an SLW assay with five tubes per specimen for a total of 15 tubes per workflow.

Consistent Reagent and Instrument Performance and Streamlined AssayTransfer Enables Global Standardization

Ensuring consistent performance across the globe is critical for the distributed manufacturing and testing commonly found in cell therapy manufacturing as well as producing quality clinical research data. BD Biosciences has developed robust methods to make this easier.

Streamlined Assay Transfer for Reproducible Performance Across Manufacturing Sites

Universal Setup on the BD FACSLyric™ Flow Cytometer allows transfer of user-defined assays from one instrument to another, supporting standardization of conditions for reproducibility across global manufacturing sites. This high-performance, highly sensitive flow cytometer demonstrates exceptional resolution and improved separation to make dim and rare populations easier to resolve.

The BD FACSDuet™ Sample Preparation System fully automates flow cytometry sample prep, including sample washing. The BD FACSDuet™ System adds traceability and automation to the preanalytical process.

BD Clinical Discovery Research Reagents are manufactured in a GMP environment to support your manufacturing QC assays. Using GMP reagents as part of your flow cytometry quality control helps to further standardize your manufacturing QC assay to give you confidence in the safety and integrity of your clinical research. Lot-to-lot consistency leads to results that increase confidence in the data and that it can be safe for translating into clinical use in the future.

BD RUO (GMP) Reagents are manufactured in accordance with Good Manufacturing Practices for devices under 21 CFR Part 820. Unit-sized preformulated and performance-optimized multicolor RUO/GMP panels are also available.

Custom multicolor panel solutions are also available to drive workflow efficiency and assay standardization. These reagents, defined by the customer, are manufactured using proprietary BD Horizon™ Chroma Dried Paneland are stable for 12–18 months at room temperature.

View Available RUO/GMP Reagents

A user-defined assay across three instruments shows the performance of Universal Setup on the BD FACSLyric™ System.

Functions in the BD FACSuite™ Application Assist in Supporting Your 21 CFR Part 11 Compliance and Electronic Record Integrity

Our flagship analyzer, BD FACSLyric™ Flow Cytometer, is upgradeable to a 12-color configuration. It is powered by the BD FACSuite™ Application used for acquisition and analysis that helps to support 21 CFR Part 11 compliance with password protection, electronic signatures, automatic record keeping and audit trails. We provide operational qualification (OQ) by a BD field service engineer for features related to 21 CFR Part 11 compliance for the BD FACSLyric™ Flow Cytometer and the BD FACSuite™ Application.

The BD FACSDuet™ Premium System allows traceability of samples and worklists through carrier barcoding and supports ISO 15189-accredited labs with compliance with complete workflow traceability.

Automated systems and software such as the BD FACSuite™ Application include built-in functional controls that helps to achieve compliance with the functional aspects of 21 CFR Part 11. However, there are limitations to what the tools can provide.

Learn how the BD FACSuite™Application functions and options support 21 CFR Part 11.

Webinar: 21 CFR Part 11 Compliance.

Learn about the:

- Background and overview of 21 CFR Part 11

- Importance of data security practices for open vs closed systems

- Crucial role software plays in enabling 21 CFR Part 11 compliance

- Guidelines for electronic signatures and records

Global Install Base with Guaranteed Technical Service Support

With BD as your single partner for flow cytometry reagents, instruments and services you will benefit from synergies in user workflows and support provided. BD Technical Services provide installation qualification (IQ), operational qualification (OQ) and technical service support to minimize instrument downtime. BD offers qualification assistance to help customers meet current Good Manufacturing Practice (cGMP) and Good Laboratory Practice (cGLP) standards. Explore our contract manufacturing offering of multicolor panels in liquid, dried or lyophilized formats to minimize errors and time associated with manual cocktailing of reagents.

The BD FACSLyric™ Flow Cytometer has an install base of more than 3,000 units around the world. BD Biosciences has service engineers and application specialists available across North and South America, Africa, Europe and Asia to support your needs as you look to scale up operations.

All user-defined flow cytometry assays used for manufacturing and QC release of product must be validated and verified by the user. The user must comply with applicable local regulations and obtain appropriate health authority approval as necessary for their intended use.

Submit your inquiry to have a BD representative reach out to you

*Required fields

BD FACSLyric™ Flow Cytometers are Class 1 Laser Products.

The BD FACSLyric™ Flow Cytometer is For Research Use Only. Not for use in diagnostic or therapeutic procedures.

The BD FACSLyric™ Flow Cytometer is for Research Use Only with BD FACSuite™ Application for up to 12 colors. Not for use in diagnostic or therapeutic procedures.

The BD FACSDuet™ Sample Preparation System is for In Vitro Diagnostic Use. Sample preparation for user defined protocols and cocktailing functions are for Research Use Only. Not for use in diagnostic or therapeutic procedures.